In the realm of metallurgy, stainless steel is renowned for its durability, corrosion resistance, and versatility. Stainless steel has carved its niche in an array of industries, from construction to aerospace. In this article, we delve into the intricate world of stainless steel production and processing, uncovering the secrets that make it a material of choice for countless applications.

The Composition That Sets It Apart

Stainless steel owes its exceptional properties to its unique composition. It primarily consists of iron, carbon, and a minimum of 10.5% chromium. This essential alloying element is the secret behind stainless steel's resistance to rust and corrosion. Additionally, other elements like nickel, molybdenum, and titanium can be added to enhance its characteristics for specific applications further.

The Stainless Steel Production Process

Melting and Formation

Stainless steel production commences with the melting of raw materials in electric arc furnaces. These raw materials typically include scrap metal, iron ore, and alloying elements like chromium and nickel. The intense heat of the furnace transforms these materials into a molten state, ready for the next phase.

Casting and Forming

Once molten, the stainless steel is cast into various shapes through a process called continuous casting. This results in the formation of slabs, billets, or blooms, depending on the intended end product. These initial forms are then further processed through rolling or forging to achieve the desired dimensions and shapes.

Heat Treatment

Heat treatment is a critical step in enhancing the mechanical properties of stainless steel. This process involves heating the metal to specific temperatures and then cooling it rapidly or gradually, depending on the desired outcome. Heat treatment can improve the stainless steel's hardness, strength, and ductility.

Cold Rolling and Annealing

Cold rolling is employed to reduce the thickness of stainless steel sheets and coils, resulting in improved surface finish and dimensional accuracy. After cold rolling, annealing is performed to relieve internal stresses and restore the material's ductility.

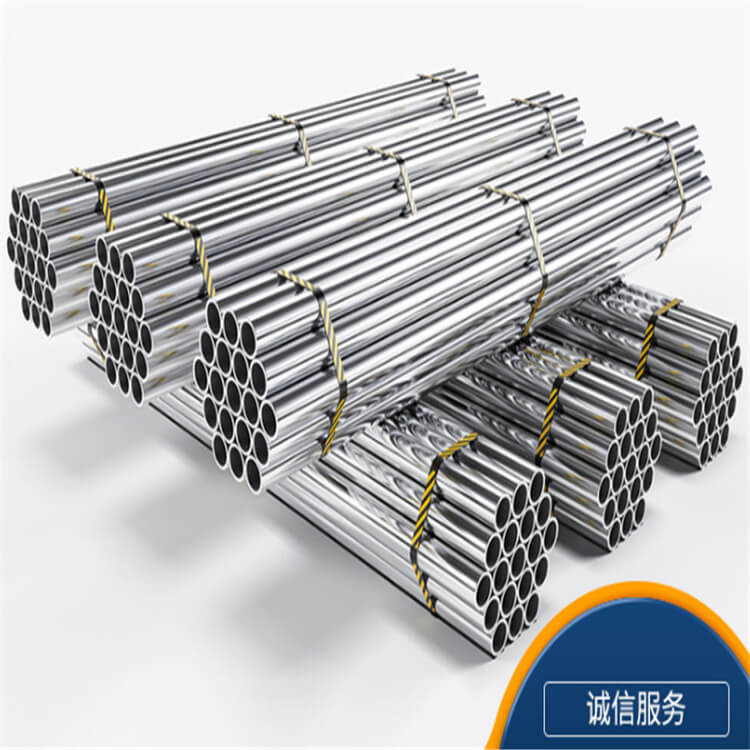

Stainless Steel Heating Tube

The Magic of Stainless Steel: Properties and Applications

Impenetrable Corrosion Resistance

Stainless steel's resistance to corrosion is its hallmark feature. The chromium present in the alloy forms a protective oxide layer on the surface when exposed to oxygen, preventing rust and corrosion. This makes stainless steel ideal for outdoor structures, kitchen appliances, and marine applications.

Strength Meets Versatility

Stainless steel isn't just about corrosion resistance; it boasts exceptional strength as well. Its ability to withstand high temperatures and extreme pressures makes it indispensable in industries such as construction, automotive manufacturing, and aerospace.

Aesthetic Appeal

Beyond its functional attributes, stainless steel also offers aesthetic appeal. Its sleek, polished surface lends a touch of modern elegance to architectural designs, kitchen appliances, and decorative elements.

Hygiene and Healthcare

Stainless steel's non-porous surface makes it an excellent choice for applications where hygiene is paramount, such as medical equipment, food processing, and pharmaceuticals.

Sustainability in Action

Stainless steel is inherently sustainable, as it can be recycled repeatedly without losing its quality. This eco-friendly aspect further solidifies its position as a responsible choice in

Innovations in Stainless Steel Processing

Advanced Alloys

Innovations in metallurgy have led to the development of advanced stainless steel alloys with tailored properties. These alloys are designed to excel in specific environments, from high-temperature industrial settings to aggressive chemical applications.

Precision Fabrication Techniques

Modern machining and fabrication technologies have revolutionized the way stainless steel components are manufactured. CNC machining, laser cutting, and 3D printing have opened up new possibilities for intricate and precise designs.

Conclusion

In the ever-evolving world of materials science, industrial stainless steel remains an enduring favorite. Its remarkable blend of strength, corrosion resistance, and versatility has made it an indispensable asset across industries. In the quest for excellence, stainless steel production and processing continue to evolve, offering us an array of innovative solutions that push the boundaries of what's possible.