Nowadays, many fitting pipe welding machinery co ltd provide a variety of pipe welding services, and you may want a comprehensive understanding of the stainless steel pipe welding specification. Perhaps this article can help you.

Stainless Steel Pipe Welding Specification

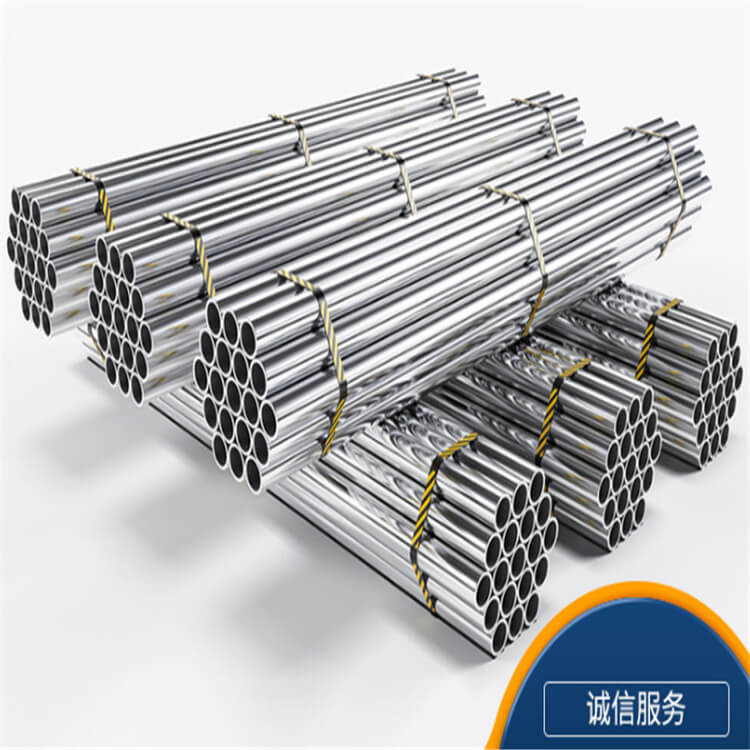

The scope of the stainless steel pipe welding specification covers seamless, straight-seam welded, and heavily cold-worked welded stainless steel pipe for high temperature and general corrosion service. And the process includes the stainless pipe being fabricated – seamless, welded or heavily cold-worked.

|

Grade |

Content % by weight |

|||||||

|

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

Chromium |

Nickel |

Molybdenum |

|

|

304 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

18 – 20 |

8 – 11 |

x |

|

304L |

0.035 |

2.00 |

0.045 |

0.030 |

1.00 |

18 – 20 |

8 – 13 |

x |

|

316 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

16 – 18 |

10 – 14 |

2 – 3 |

|

316L |

0.035 |

2.00 |

0.045 |

0.030 |

1.00 |

16 – 18 |

10 – 14 |

2 – 3 |

* Heat Treatment: All stainless steel pipe shall be furnished in heat-treated condition. Heat treat 304/L and 316/L to a minimum of 1900 degrees F (1040 degrees C), followed by quenching in water or rapid cooling.

Tensile Requirement

|

304 |

304L |

316 |

316L |

|

|

Tensile Strength, minimum PSI |

75,000 |

70,000 |

75,000 |

70,000 |

|

Yield Strength, minimum PSI |

30,000 |

25,000 |

30,000 |

25,000 |

* Hydrostatic/Non-Destructive Electrical Testing: Each stainless steel pipe shall be subjected to nondestructive electrical or hydrostatic testing. Unless otherwise specified in the purchase order, the type of used test will be selected by the manufacturer.

What Element Will Be Involved In The Stainless Steel Pipe Welding Specification?

In general, it depends on your welding projects, which may include the long seam welded pipe, welding leaking pipe, roll welding pipe, pipe welding root pass, spiral seam welded pipe, double welded pipe, chill rings for pipe welding, best welding rod for oilfield pipe, GMAW pipe welding, helical welded pipe, seamless or welded pipe, 32mm weld pipe, arc welding galvanized pipe, etc.

What Is The HDPE Pipe Welding Risk Assessment?

HDPE pipe welding is very common in many different industries. The machines used to weld HDPE pipe range from small, labor-intensive machines to easy-to-use controls and larger hydraulics machines. The HDPE welding process has many hazards to consider, so the HDPE pipe welding risk assessment is necessary.

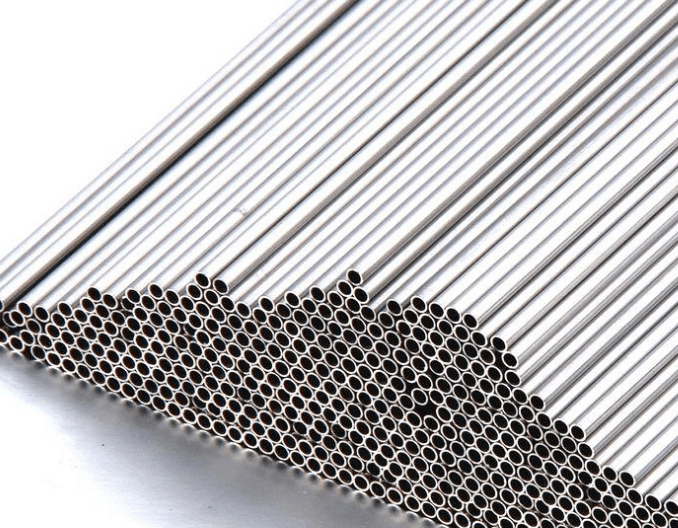

304/316L Stainless Steel Capillary

How To Stick Weld Stainless Steel Pipe?

Step 1: Place the electrodes and arc. You need to select the power supply current setting according to the welding position and electrodes. Then turn on the power supply, and the current will flow through them.

Step 2: The arc length may vary - not all electrodes and projects require the same. Therefore, choosing the proper arc length for stick welding is critical.

Step 3: Once the electrode begins to melt, the consumable flux coating of the electrode will create a gas cloud, protecting the soft steel and preventing oxidation.

Step 4: This gas cloud will form a molten pool as it cools and forms a solid joint. And it would be best if you chose the right travel angle for the arc during this entire process. (The wrong angle will affect the travel speed.)

How To Weld Galvanized Steel Pipe?

-

Set up a safe working area

- * Get a series of protective tools for welding - welding mask, gloves, apron, etc.

- * Use a fume extractor or install a fan next to the welding site to blow the zinc fumes away

- * Ground the welder by placing the claw on the fixture or work surface

-

Sanding and Securing

- * Grind off the galvanized coating on the welded area

- * Place your 2 pieces together

- * Use a welding jaw to hold smaller parts

-

Using the welder

- * Use an arc welder to weld galvanized steel

- * Choose the welding rod according to the size of the metal

- * If you are joining 2 pieces, start at the end of the seam

- * Work forward and backwards to apply flux and heat it up

- * Weld around the edges of the tear

Final Word

Above are some tips for the stainless steel pipe welding specification you may want to know. If you want more details about the stainless steel products, please feel free to contact us!