Stainless steel is a highly durable and versatile material used in various industries, including construction, automotive, and aerospace. It is a popular choice due to its resistance to corrosion, heat, and high-pressure environments. However, to fully utilize the unique properties of stainless steel, it must undergo deep processing. In this article, we will discuss the deep processing of stainless steel and its significance in various industries.

What is Deep Processing of Stainless Steel?

Deep processing of stainless steel refers to the various manufacturing techniques used to transform raw stainless steel materials into finished products. This involves a series of complex operations such as cutting, shaping, forming, welding, and polishing. Deep processing aims to enhance the properties of stainless steel, such as its strength, ductility, and corrosion resistance, and to make it suitable for specific applications.

Significance of Deep Processing of Stainless Steel

Deep processing of stainless steel plays a vital role in several industries, including:

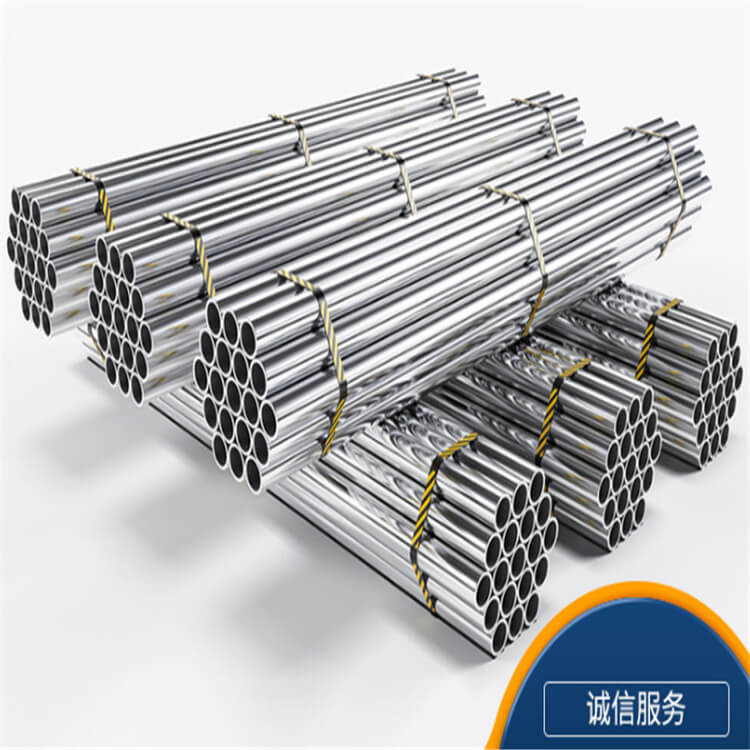

Construction: Stainless steel is widely used in construction due to its durability and corrosion resistance. Deep processing techniques such as welding, bending, and cutting are used to manufacture stainless steel products like pipes, bars, and sheets that are used in construction.

Automotive: The automotive industry uses stainless steel extensively in car manufacturing due to its high strength and corrosion resistance. Deep processing techniques such as stamping, forging, and welding are used to produce various parts, including exhaust systems, fuel tanks, and body panels.

Aerospace: The aerospace industry relies on stainless steel for its high strength and resistance to extreme temperatures and pressures. Deep processing techniques such as machining, drilling, and welding are used to produce critical components such as turbine blades and engine parts.

Medical: Stainless steel is used in medical applications such as surgical instruments, implants, and medical devices due to its biocompatibility and corrosion resistance. Deep processing techniques such as electro-polishing and precision machining are used to produce highly accurate and durable medical instruments and implants.

Types of Deep Processing Techniques for Stainless Steel

Machining: Machining involves removing material from a stainless steel workpiece to create a desired shape or size. This can be done using various methods such as drilling, milling, and turning.

Welding: Welding is a process that joins two stainless steel pieces together by melting them at their joint using heat and pressure. Welding is a critical deep processing technique used in various industries, including construction, automotive, and aerospace.

Forming: Forming involves reshaping a stainless steel workpiece by bending, stamping, or forging. This technique is used to produce various stainless steel products such as pipes, bars, and sheets.

Polishing: Polishing involves smoothing the surface of a stainless steel workpiece to improve its appearance and corrosion resistance. This technique is commonly used in the manufacturing of medical instruments and implants.

Conclusion

The deep processing of stainless steel is a crucial step in transforming raw materials into finished products suitable for various industries. The different deep processing techniques used, including machining, welding, forming, and polishing, help enhance the unique properties of stainless steel, making it suitable for specific applications. As demand for stainless steel products continues to rise, manufacturers must invest in high-quality deep processing equipment and skilled labor to meet the market's needs.