When it comes to stainless steel tubes, there are two common options to consider: cut-to-size and standard tubes. These two choices have their own unique advantages and applications. In this article, we will explore what they can bring to your projects and help you understand which option is best suited for your specific requirements.

What are Cut-to-Size Stainless Steel Tubes?

Cut-to-size stainless steel tubes are precisely tailored to meet specific dimensions requested by customers. These tubes are manufactured to custom lengths, diameters, and thicknesses, ensuring a perfect fit for a particular project or application. Cut-to-size tubes offer flexibility and customization, making them a popular choice in various industries.

What are Standard Stainless Steel Tubes?

On the other hand, standard stainless steel tubes are pre-manufactured in standardized lengths, diameters, and thicknesses. These tubes are readily available in the market and are commonly used in a wide range of applications. Standard tubes are produced in large quantities, resulting in cost-effective pricing and quicker availability.

The Advantages of Cut-to-Size Stainless Steel Tubes

Now that we have a basic understanding of the two options, let's delve deeper into the benefits of cut-to-size stainless steel tubes.

1. Customization to Fit Your Requirements

One of the biggest advantages of cut-to-size stainless steel tubes is the ability to customize them to fit your specific requirements. Whether you need a particular length, diameter, or thickness, cut-to-size tubes can meet your project needs perfectly. This level of customization ensures a perfect fit, reducing waste and optimizing efficiency.

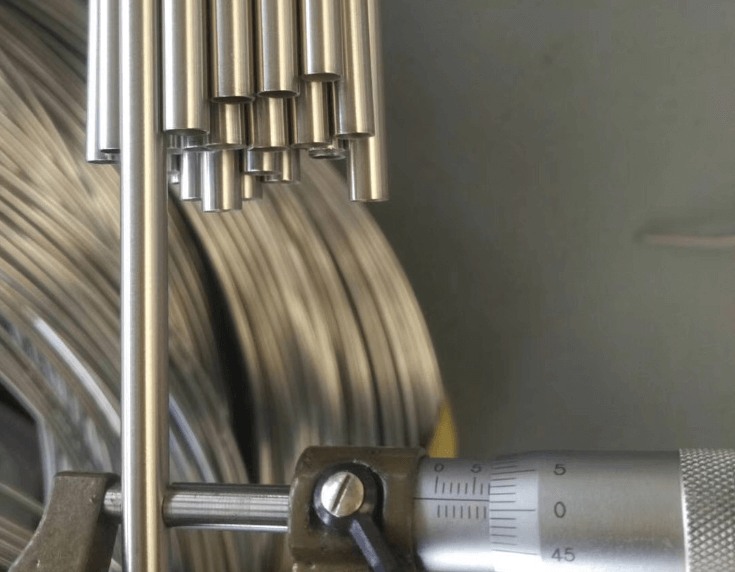

2. Enhanced Precision and Accuracy

Cut-to-size tubes offer enhanced precision and accuracy compared to standard tubes. When you require tight tolerances or specific measurements, cut-to-size tubes provide the level of precision necessary for your application. Whether it's for critical engineering projects or intricate architectural designs, the precision of cut-to-size stainless steel tubes is unparalleled.

3. Wide Range of Applications

The versatility of cut-to-size stainless steel tubes makes them suitable for a wide range of applications. From construction and manufacturing to automotive and aerospace industries, cut-to-size tubes find their place in various sectors. Whether you need tubes for structural support, fluid transportation, or aesthetic purposes, cut-to-size options can be customized to meet your specific application requirements.

Cut-To-Size Stainless Steel Tubes

The Benefits of Standard Stainless Steel Tubes

While cut-to-size tubes offer customization and precision, standard stainless steel tubes also have their own set of benefits that make them a popular choice in many scenarios.

1. Cost-Effective Solution

Standard stainless steel tubes are produced in large quantities, resulting in cost-effective pricing. If your project doesn't require custom dimensions or specialized requirements, standard tubes offer an economical solution. These readily available tubes can be purchased in bulk, saving both time and money.

2. Quick Availability

Another advantage of standard stainless steel tubes is their quick availability. Since they are produced in large volumes, standard tubes are readily stocked by suppliers and distributors. If you have a time-sensitive project or need immediate access to stainless steel tubes, standard options can be a reliable and convenient choice.

3. Versatile Applications

Standard stainless steel tubes are widely used in various applications due to their versatility. From plumbing and HVAC systems to structural frameworks and decorative purposes, standard tubes serve diverse industries and requirements. Their standardized dimensions make them compatible with existing systems and allow for easy replacement or integration.

Conclusion

By understanding the advantages and limitations of both options, you can make an informed decision that aligns with your project's needs. Remember to work with a reputable stainless steel tube manufacturer who can provide quality stainless steel tubes for your specific requirements.