Cut-to-size stainless steel, a versatile and indispensable material, plays a pivotal role in numerous industries and applications due to its exceptional properties. In this article, we will uncover the advantages it offers over traditional steel materials and delve into the various cutting methods and factors to consider when ordering, ensuring you have a comprehensive understanding of this remarkable material.

Advantages of Using Cut-to-Size Stainless Steel

Precision and Customization

Cut-to-size stainless steel provides unparalleled precision and customization. This material can be tailored to exact dimensions and specifications, catering to the unique needs of various industries. Whether you require intricate designs or specific shapes, cut-to-size stainless steel ensures your project aligns perfectly with your vision.

Material Efficiency

One of the standout advantages of cut-to-size stainless steel is its material efficiency. Unlike standard steel sheets, which often result in excessive waste due to unused portions, cut-to-size stainless steel minimizes material wastage. This efficiency not only benefits your bottom line but also reduces environmental impact.

Reduced Waste

The reduction in waste goes hand in hand with material efficiency. Cut-to-size stainless steel eliminates the need for excess material, contributing to a cleaner and more sustainable production process. This is particularly important in today's environmentally conscious world.

Cost Savings

While the initial cost of cut-to-size stainless steel may seem higher than that of standard sheets, the long-term cost savings are substantial. The reduction in waste, customization options, and durability of stainless steel make it a cost-effective choice for a wide range of applications.

cut-to-size stainless steel wholesale

Applications of Cut-to-Size Stainless Steel

Architectural and Construction

Cut-to-size stainless steel finds extensive use in architectural and construction projects. Its corrosion resistance, strength, and aesthetic appeal make it an ideal choice for structural elements, cladding, and decorative features in modern buildings.

Automotive Industry

In the automotive industry, precision and durability are paramount. Cut-to-size stainless steel components are crucial for manufacturing parts that need to withstand harsh conditions, ensuring the longevity and safety of vehicles.

Aerospace and Aviation

The aerospace and aviation sectors demand materials that can withstand extreme conditions. Cut-to-size stainless steel is prized for its resistance to corrosion and high temperatures, making it a vital component in aircraft, spacecraft, and related equipment.

Food Processing and Hygiene

Stainless steel's hygienic properties and corrosion resistance make it the preferred choice in the food processing industry. Cut-to-size stainless steel components are used in everything from food production machinery to kitchen equipment, ensuring food safety and quality.

Factors to Consider When Ordering Cut-to-Size Stainless Steel

Alloy Selection

Choosing the right stainless steel alloy is essential. Factors such as corrosion resistance, temperature resistance, and strength requirements should guide your selection process.

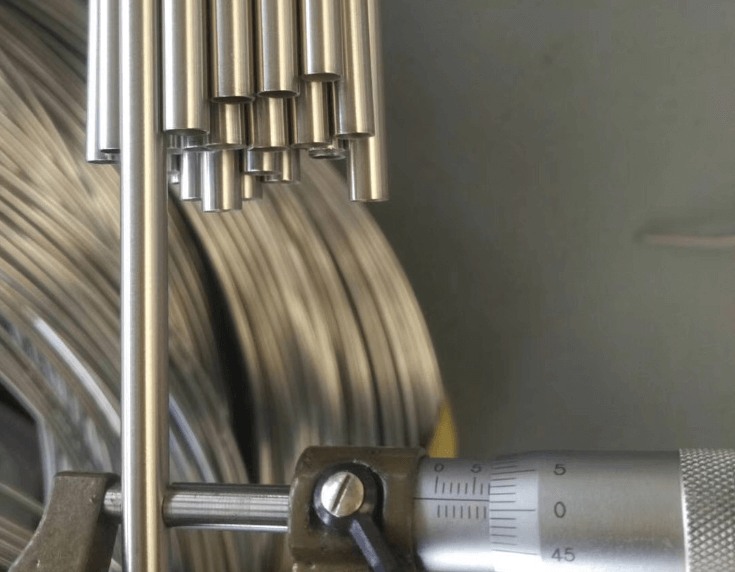

Thickness and Dimensions

Specify the thickness and dimensions accurately. This ensures that the cut-to-size stainless steel meets your project's structural and functional requirements.

Surface Finish

Consider the desired surface finish, whether it's a polished, brushed, or matte appearance. The finish can impact the material's aesthetics and performance.

Tolerances and Specifications

Clearly communicate any tolerances and specifications required for your project. This will prevent discrepancies and ensure the cut-to-size stainless steel meets your expectations.

Conclusion

Cut-to-size stainless steel is a versatile and indispensable material that offers precision, efficiency, and versatility. By harnessing the advantages of cut-to-size stainless steel, you can elevate the quality and performance of your projects while minimizing waste and costs. Whether you're in construction, manufacturing, or any other industry, this remarkable material has the potential to revolutionize your work.