Stainless steel, a versatile and durable alloy, has become a cornerstone material in modern industries. Its exceptional properties, such as corrosion resistance, strength, and hygienic qualities, make it a preferred choice for various applications, from kitchenware and construction to medical instruments and aerospace components. To better understand how stainless steel takes shape, let's delve into the intriguing world of stainless steel processing.

Manufacturing Processes for Stainless Steel

Melting and Casting

The journey of stainless steel starts with the melting and casting phase. This intricate process involves the combination of raw materials, including iron ore, nickel, chromium, and other elements, in precise proportions. The mixture is then melted in electric arc furnaces or induction furnaces, creating a homogeneous molten alloy. The molten metal is cast into specific shapes using various casting methods, such as continuous casting or ingot casting. This initial stage sets the foundation for the quality and composition of the stainless steel.

Hot Rolling

Once the stainless steel is cast into ingots or slabs, the next step is hot rolling. This high-temperature process involves passing the metal through a series of rollers to reduce its thickness and refine its grain structure. Hot rolling enhances the mechanical properties of the steel, making it more malleable and easier to shape. The sheets or coils produced through hot rolling serve as the basis for many end products, from kitchen appliances to architectural components.

Cold Rolling

Cold rolling is a subsequent step in the stainless steel processing journey. In this process, the hot-rolled stainless steel undergoes further reduction in thickness at room temperature. Cold rolling imparts a smoother and more polished surface finish, improving the steel's aesthetics and dimensional accuracy. Additionally, it enhances the material's strength and hardness, making it ideal for precision applications such as automotive components and medical equipment.

Annealing and Pickling

Annealing is a crucial heat treatment process in stainless steel manufacturing. After cold rolling, stainless steel is annealed to relieve internal stresses and promote grain growth. This ensures the material maintains its desired properties while also becoming more ductile. Subsequently, pickling is performed to remove any surface impurities and oxide layers, further enhancing the corrosion resistance of the stainless steel.

Stainless Steel Finishing Techniques

Surface Grinding

Surface grinding is an essential finishing technique employed to achieve a smooth and flat surface on stainless steel products. Using abrasive wheels, the process removes unevenness and imperfections, resulting in a refined and flawless surface finish. Surface grinding is commonly used in manufacturing applications where precision and uniformity are paramount, such as in the production of industrial machinery components and medical implants.

Polishing and Buffing

Polishing and buffing are two complementary processes that enhance the aesthetic appeal of stainless steel. Polishing uses abrasives to create a reflective surface, while buffing employs soft pads and compounds to bring out a brilliant shine. These techniques are extensively employed in the fabrication of luxury goods, architectural fittings, and high-end consumer products that demand an impeccable, mirror-like finish.

Electropolishing

Electropolishing is a specialized electrochemical process that offers superior surface finishing for stainless steel. Unlike traditional mechanical methods, electropolishing selectively removes surface material, leaving the underlying metal smoother and free of micro-crevices. The result is a highly sanitary and corrosion-resistant surface, making electropolishing a popular choice in pharmaceutical equipment, food processing machinery, and semiconductor components.

Passivation

Passivation is the final touch in the finishing process for stainless steel. It involves treating the metal with a chemical solution, typically based on nitric or citric acid, to create a passive oxide layer. This layer protects the steel from corrosion and contamination, ensuring its long-term durability and reliability. Passivation is a vital step in the production of stainless steel components used in demanding environments, such as marine applications and aerospace structures.

Stainless Steel Forming Methods

Sheet Metal Forming

Sheet metal forming is a versatile technique that allows stainless steel to take on various shapes and configurations. Using processes like bending, deep drawing, and punching, stainless steel sheets are transformed into intricate designs used in automotive body panels, kitchen sinks, and electrical enclosures.

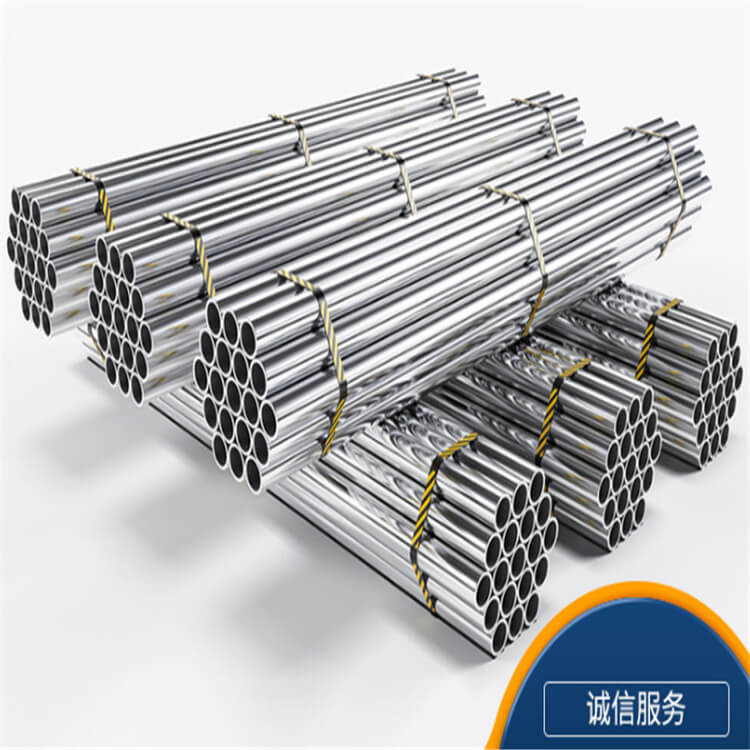

Welding and Fabrication

Welding plays a significant role in shaping stainless steel into complex structures and assemblies. Various welding methods, such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and laser welding, are employed to join stainless steel components seamlessly. Fabrication processes, including cutting, bending, and assembling, are then applied to create finished products such as industrial tanks, architectural frameworks, and aerospace structures.

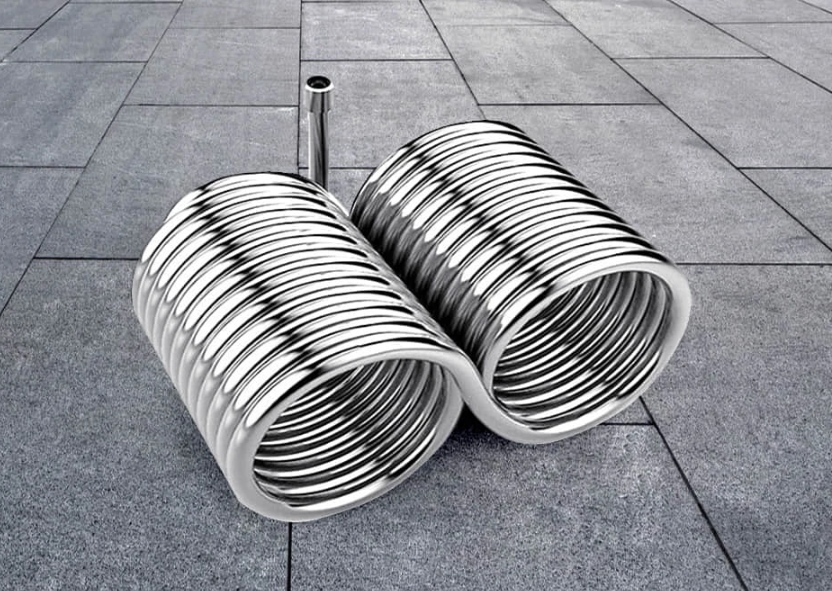

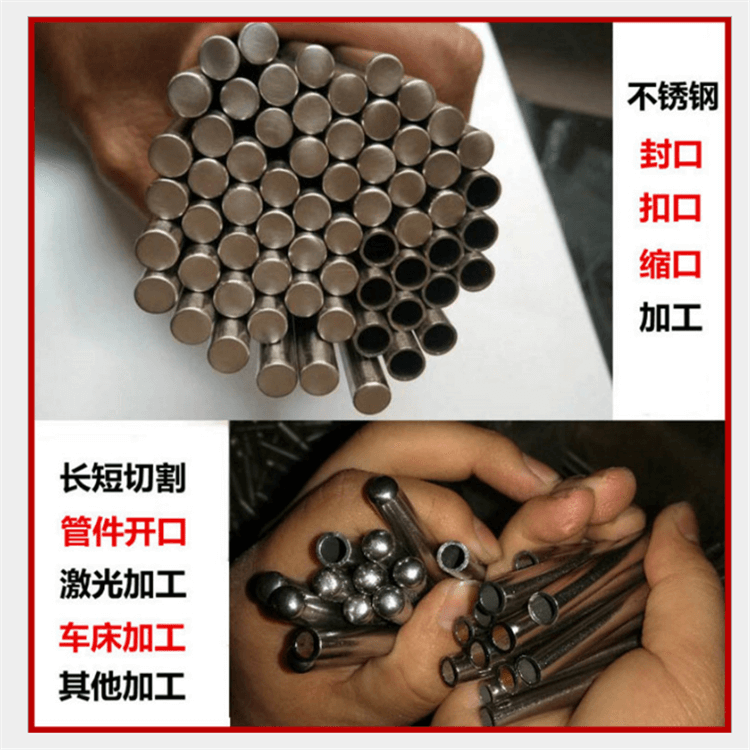

Tube and Pipe Bending

Stainless steel tubes and pipes are crucial components in fluid transportation and structural applications. Tube and pipe bending processes, utilizing mandrels and dies, allow stainless steel to be shaped into precise angles and curves. This capability is widely utilized in industries like construction, automotive, and oil and gas, where durable and corrosion-resistant pipelines are essential.

Extrusion

Extrusion is a specialized forming method used to create complex cross-sectional profiles of stainless steel. Through the application of heat and pressure, the metal is forced through a die, resulting in long, continuous shapes. Extruded stainless steel finds applications in architectural trim, automotive trims, and custom-designed components requiring unique profiles.

Conclusion

The world of stainless steel processing is a realm of precision and craftsmanship. From the initial melting and casting to the intricate finishing and forming techniques, each step contributes to the creation of a material that stands strong against corrosion, time, and extreme environments.

The versatility and resilience of stainless steel ensure it remains a cherished resource across industries, advancing innovation and shaping the infrastructure of our modern world. Please feel free to contact us at [email protected] for further information about our top-quality stainless steel processing!